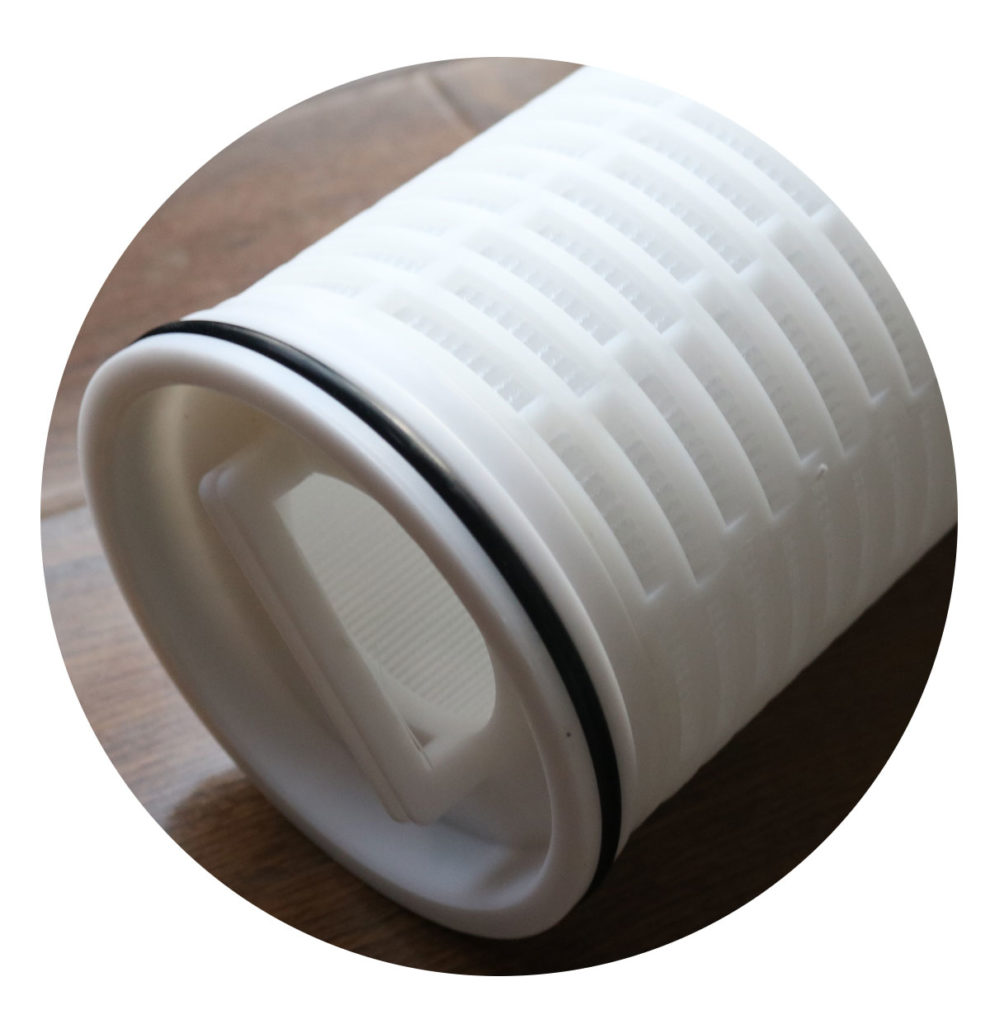

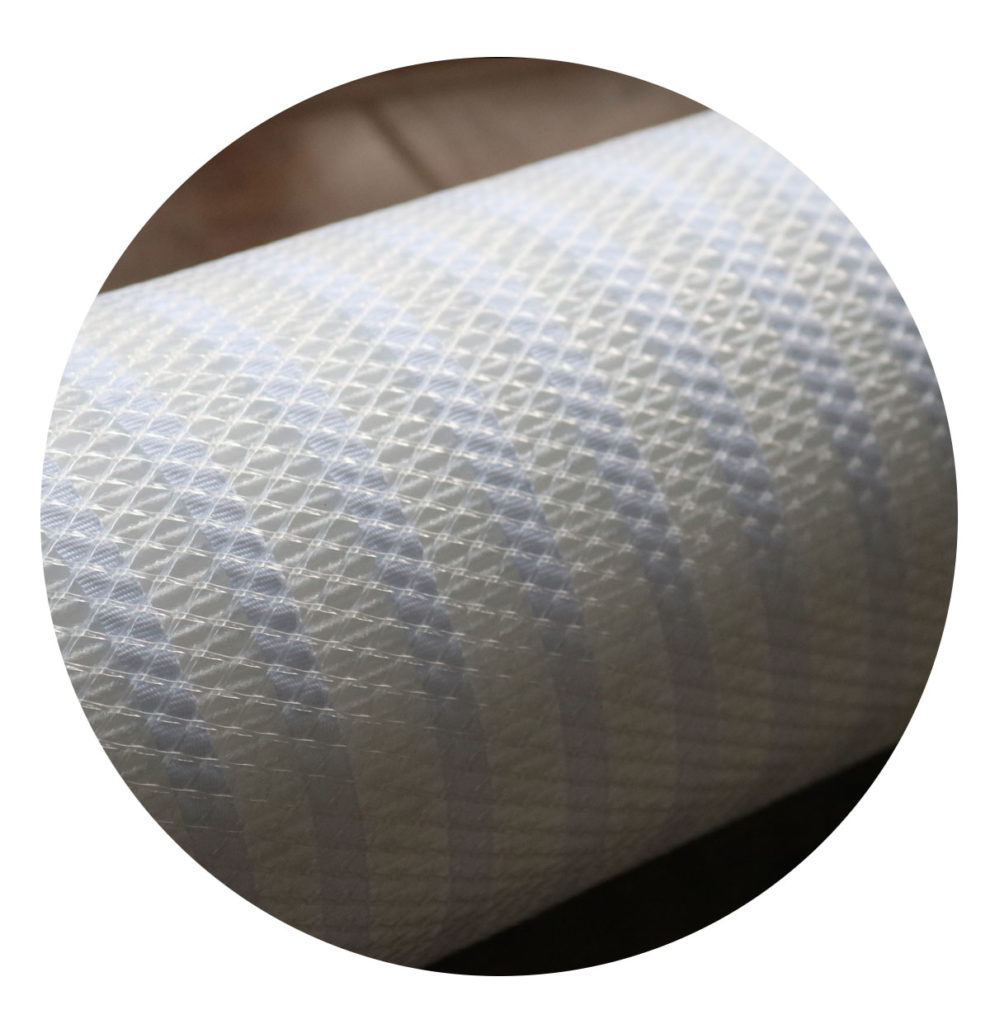

Puritech Ultraflow-P High Flow Filter Cartridge is the retrofit of Pall Ultipleat high flow filter cartridges utilize pleated depth media offering large surface area, maximum efficiency and exceptionally high flow capabilities. Developed to suit industrial processes where high performance is required, the low pressure drop and high dirt holding capacity make it the ideal choice for fine polishing applications. Two media options are offered as standard, the Polypropylene and Glass Microfiber. The PP standard range is manufactured using all polypropylene and designed for wide chemical compatibility. The GF standard range will be ideal choices for higher temperatures and extremely high dirt holding capacity. Thermal welding processes seal all components, eliminating adhesives and extractables and optimizing cartridge integrity.

Features and Benefits:

- High surface area, resulting in low pressure drop and excellent dirt holding capacity

- 100% thermally welded construction for maximum integrity and strength, up to 1541mm (60”)

- Internal support core for resistance to back pressure

- Low maintenance cost and fewer number of cartridges

Material:

- Filter medium: Polypropylene/ Glass micro fiber

- Inner Core: Reinforced Polypropylene

- End caps: Reinforced Polypropylene

- O-ring : NBR/EPDM/Silicone/Viton

Dimension:

- Outer Diameter: 6″/ 152mm

- Removal Rating : 1μm, 3μm, 5μm, 10μm, 30μm, 50μm, 70μm

- Length : 20″, 40″, 60″

- Filtration Area: 3.3 m², 6.5 m², 9.8m²

Recommended operation condition:

- Maximum Temperature: PP: 4 bar@82℃, GF: 3.4 bar@121℃

- Maximum Pressure: PP: 82℃, GF: 121℃

- Maximum Flow rate: 660LPM@20” 1300LPM@40”, 1900LPM@60”

- Recommended Change-out Differential Pressure: 2.4 bar @20 ℃

Typical Application:

- Water Treatment: Pre reverse osmosis, UV protection, Resin trap, Cryptosporidium removal

- Food and Beverage: Bottled water, Beers, Wines, Flavors, Polishing lines, General clarification

- Fine Chemicals: Polymers, Acids, Bases, Solvents

1, Casing style

2, Belting style

3, Net style